- Home

- Products

- Lamination Machines

- Nonwoven to Nonwoven

Nonwoven to Nonwoven

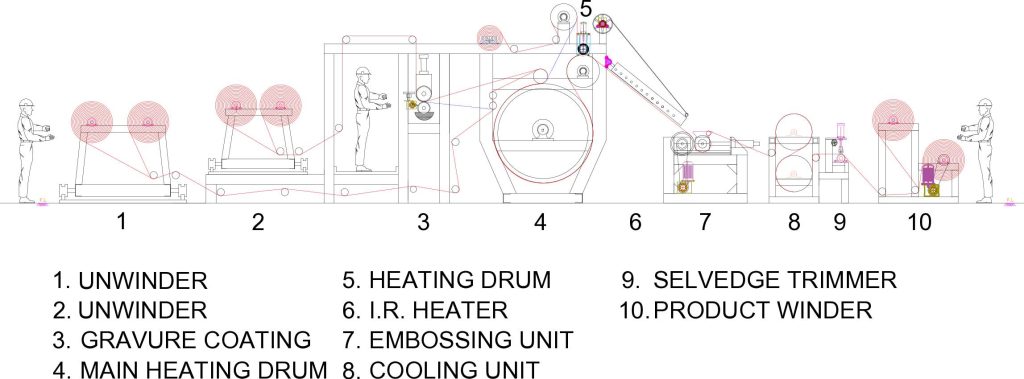

Machine Diagram

The Nonwoven-to-Nonwoven Lamination Machine is specifically designed for bonding two layers of nonwoven fabric to create a reinforced material with enhanced strength and functionality. This lamination process is widely used in industries such as medical, hygiene, automotive, and filtration, where durability and performance are critical. With advanced lamination techniques, the machine ensures precise bonding while maintaining the breathability and softness of the nonwoven materials.

| Technical Specification | |

|---|---|

| Web width | 1600mm to 4400mm |

| Coating method | Gravour Coating, |

| Heating system | Thermic oil, Steam line, Gas burner or IR heater |

| Main Cylinder diameter | 1000mm 1200mm 1500mm |

Precise Lamination | Enhanced Material Strength | Retention of Breathability | Soft and Flexible Output | High-Speed Production | Energy-Efficient Operation | Customizable Settings | Uniform Bonding | Low Maintenance | Cost-Effective Solution

Market Focus

Surgical gowns, masks, diapers

Interior linings, soundproofing materials

Air and liquid filtration media

Furniture linings, upholstery