- Home

- Products

- Inspection & Batching

- Product Inspection

- Fully Automated PLC-Based Product Inspection

Fully Automated PLC-Based Product Inspection

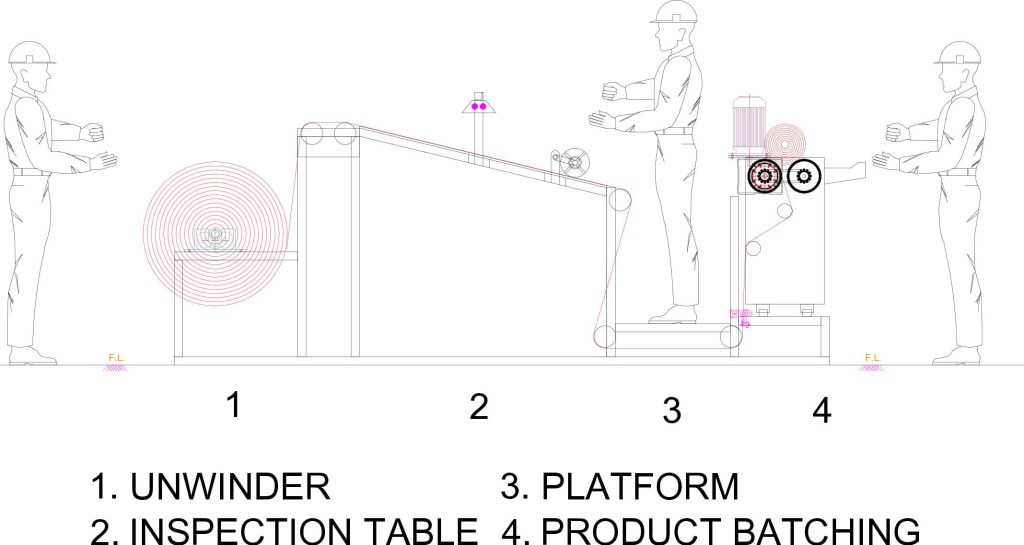

Machine Diagram

The Fully Automated PLC-Based Product Inspection Machine offers advanced capabilities for high-speed, high-accuracy inspection of various materials used in the manufacturing process. This inspection system leverages a sophisticated PLC control system, enabling seamless integration with existing production lines. The machine is equipped with automated defect detection tools, including high-resolution cameras, sensors, and light sources, ensuring precise identification of any flaws such as tears, discoloration, wrinkles, or other material inconsistencies. With its fully automated design, it minimizes manual intervention, reduces human error, and optimizes overall production efficiency, making it an essential tool for industries requiring flawless material quality.

| Technical Specification | |

|---|---|

| Web width | 1600mm to 4400mm |

High-speed automated Inspection | Fully PLC-Controlled System | Automated Defect Detection | Real-time monitoring | Seamless Integration with Production Lines | Minimal Manual Intervention | High Accuracy and Precision | Reduced Human Error | Increased Production Efficiency | Continuous Roll Monitoring | Customizable Lighting for Optimal Inspection | Real-Time Alerts and Notifications | High-Speed Winding Capability | Low Maintenance | Energy-Efficient Operation

Market Focus

Automated quality control of fabric rolls

Precision inspection of leather rolls for defects

Inspection of plastic films and packaging materials

Inspection of materials for automotive upholstery and components

Defect detection in nonwoven fabrics used for medical products

Quality control for textiles and leather in apparel, accessories, and home furnishings