- Home

- Products

- Lamination Machines

- Fabric to Fabric

- Multi-Layer Lamination

Multi-Layer Lamination

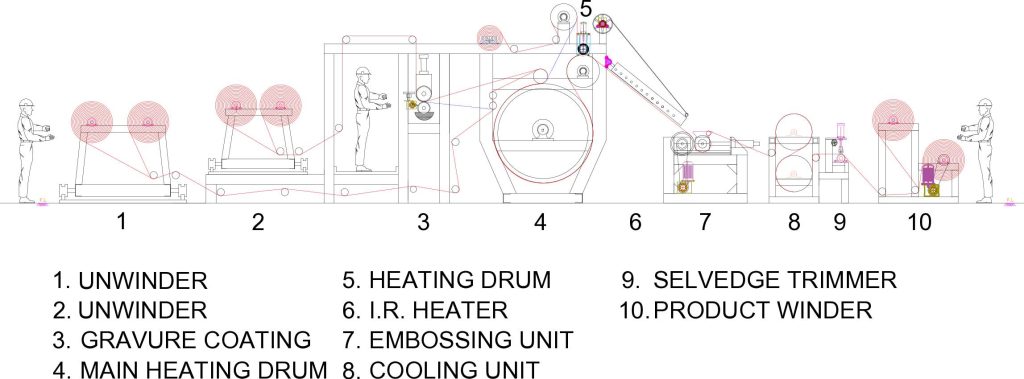

Machine Diagram

The Multi-Layer Lamination Machine is engineered to laminate three or more layers of fabric, offering enhanced structural integrity and functionality. This process allows the application of various coatings and adhesives between fabric layers, providing added benefits such as water resistance, thermal insulation, and strength. Multi-layer lamination is ideal for high-performance fabrics used in industries such as automotive, aerospace, construction, and protective wear. By creating multiple bonded layers, this machine ensures superior fabric durability, flexibility, and multi-functional properties for diverse applications.

| Technical Specification | |

|---|---|

| Web width | 1600mm to 4400mm |

| Coating method | Gravour Coating, |

| Heating system | Thermic oil, Steam line, Gas burner or IR heater |

| Main Cylinder diameter | 1000mm 1200mm 1500mm |

High-Strength Bonding | Multi-Layer Protection | Enhanced Insulation | Superior Durability | Versatile Applications | Customizable Layer Options | Energy Efficient | High-Speed Performance | Easy Maintenance | Cost-Effective Solution | Reliable and Long-Lasting

Market Focus

Interior components, seat covers, thermal insulation

Protective coverings, insulation fabrics

Fire-resistant suits, protective gear

Multi-layer tents, outdoor gear

Geotextiles, reinforced fabrics