- Home

- Products

- Coating Machine

- Direct Coating

- Two-Layer Coating

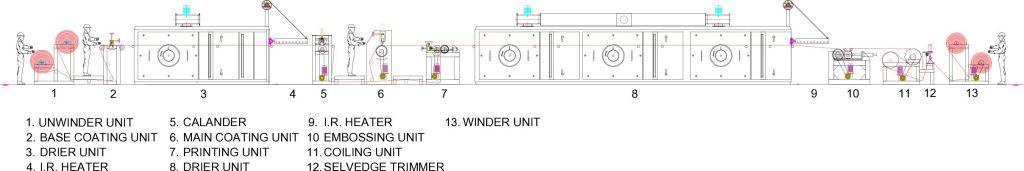

Two-Layer Coating

Machine Diagram

The Two-Layer Coating Machine applies two distinct layers of coating to the fabric, enhancing its properties for more specialized applications. The first layer is typically designed for durability, providing strength and abrasion resistance, while the second layer offers additional functionality, such as waterproofing, flame retardancy, or UV protection. This versatile process is commonly used in industries requiring high-performance fabrics, including automotive, aerospace, construction, and outdoor gear. By combining multiple layers, the Two-Layer Coating Machine ensures superior fabric performance with added value for both aesthetic and functional purposes.

| Technical Specification | |

|---|---|

| Web width | 1600mm to 4400mm |

| Coating method | Knife on Roll, Knife on fabric, Gravure coating |

| Heating system | Thermic oil, Steam line, Gas burner & IR |

| Coating Range | up to 1500 GSM |

Uniform Coating | Uniform Heating| Precision Layering| High-speed Operation| Enhanced Fabric Functionality| Improved Durability| Versatile Applications| Increased Fabric Strength| Customizable Coating Options| Cost-Effective Solution| Long-Lasting Results.

Market Focus

Protective clothing, equipment, and gear

Tents, umbrellas, hot air balloons

Sportswear, performance fabrics, and accessories

Protective fabrics for reinforcement, tarps, and covers.