- Home

- Products

- Inspection & Batching

- Paper Inspection

- Paper Inspection Double Unwinder & Double Winder

Paper Inspection Double Unwinder & Double Winder

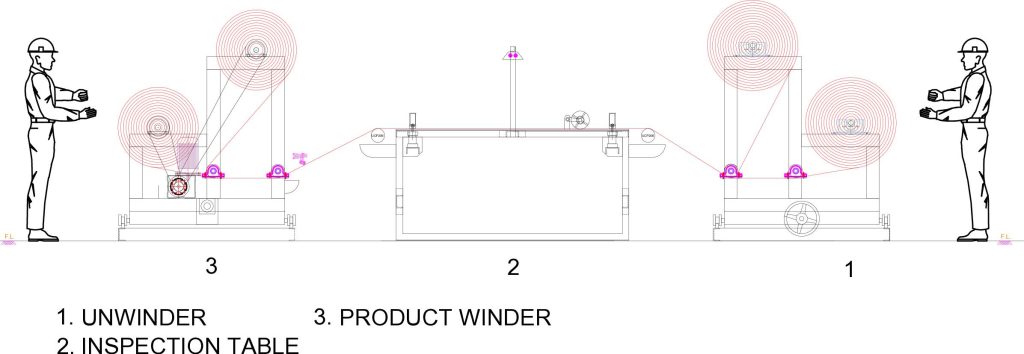

Machine Diagram

The Paper Inspection Double Unwinder & Double Winder Machine is designed to inspect and process two paper rolls simultaneously during the production process. This advanced system allows for continuous inspection without the need for manual roll changes, significantly improving production efficiency. It uses high-precision cameras, sensors, and advanced lighting systems to detect defects such as tears, wrinkles, and color inconsistencies. The double unwinding and winding mechanism ensure smooth handling of larger production volumes, and the system is equipped with automated controls for optimal performance. With its versatile design, this machine is ideal for high-capacity paper manufacturers in industries like printing, packaging, and publishing.

| Technical Specification | |

|---|---|

| Web width | 1600mm to 4400mm |

| Batching Roll Width | Up to 1500 mm |

Double Roll Unwinding & Rewinding | High-Resolution Defect Detection | Continuous Production with Minimal Downtime | Adjustable Speed & Tension Control | Easy Integration with Existing Lines | Real-Time Defect Alerts | High-Precision Paper Quality Inspection | User-Friendly PLC-Based Control System | Increased Productivity | Low Maintenance Costs | Efficient Defect Identification | Reduced Waste | Energy-Efficient Operation

Market Focus

Inspection of paper used in packaging materials

Quality control of paper for printing and publishing

Inspection of paper materials used in labels, tags, and accessories

Quality assurance for paper backing used in textiles

Inspection of recycled paper for quality and defect-free production