- Home

- Products

- Inspection & Batching

- Product Inspection

- Center Winder Type

Center Winder Type

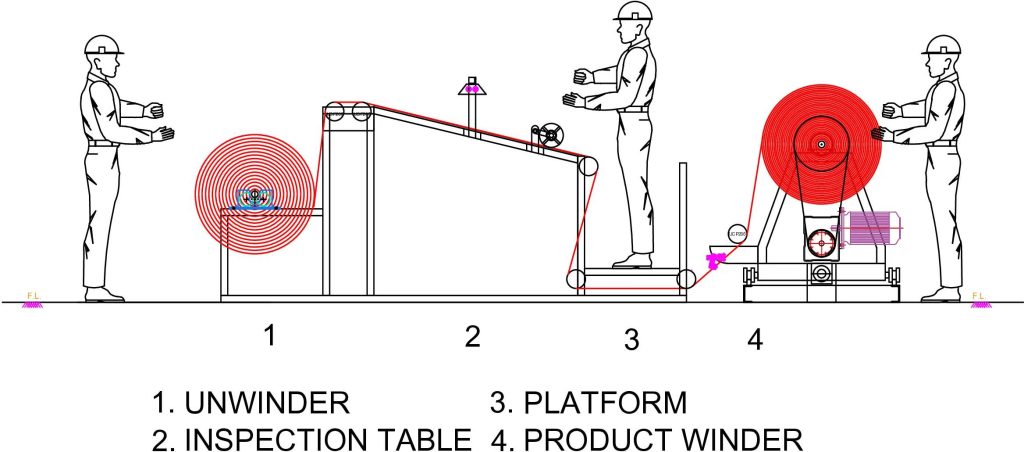

Machine Diagram

The Centre Winder Type Product Inspection Machine is designed for high-precision inspection of materials as they are wound onto a central core. This machine is ideal for inspecting larger rolls of fabrics, films, synthetic leather, and other similar materials. With its advanced defect detection capabilities, it ensures that any imperfections such as holes, scratches, or color inconsistencies are identified before the material moves forward in the production process. The Centre Winder Type Inspection Machine is built for high-speed operation and features automated systems for enhanced efficiency, reducing the need for manual inspection and improving overall production quality.

| Technical Specification | |

|---|---|

| Web width | 1600mm to 4400mm |

High-Precision Defect Detection | Central Core Winding for Efficient Material Handling | Automated Inspection System | Adjustable Winding Speed | Real-Time Monitoring and Display | Easy Integration with Existing Production Lines | High-Speed Operation | Reduced Manual Effort | Consistent Inspection Results | Enhanced Quality Control | Increased Production Efficiency | Low Maintenance | Customizable Lighting for Clear Image Capture | Optimal for Large Rolls

Market Focus

Films for packaging materials requiring adhesive bonding

Material inspection for upholstery and interior components

Quality control of large fabric rolls

Inspection of synthetic leather materials in large formats

Quality control for nonwoven fabrics used in medical products

Inspection of textiles and leather for apparel, home furnishings, and accessories